REVIEW ARTICLE

- Dubale Beyene 1

- Bereket Yonas2 2

- Umer Idris Getasew Bekele3 3

- Solomon Sisay 3

- Mesafint Mandefro 3*1*

1 Department of Veterinary Science, College of Agriculture and Natural Resources, Jinka University, Ethiopia

2* College of Veterinary Medicine, Jigjiga University, Ethiopia

3* Department of Para-clinical Studies, College of Veterinary Medicine and Animal Sciences, University of Gondar, Ethiopia. N.B: You can add the name of the editorial name to the list of authors with their respective institutions.

*Corresponding Author: Dubale Beyene

Citation: Dubale Beyene, A REVIEW ON 3D TECHNOLOGY ON MEDICAL APPLICATIONS AND ITS IMPACTS, Pharma Scope and Advances in Drug Sciences, vol 1(1). DOI: 10.9567/ISSN.2024/WSJ.98

Copyright: © 2024, Dubale Beyene, this is an open-access article distributed under the terms of The Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited

Received: October 31, 2024 | Accepted: November 02, 2024 | Published: November 21, 2024

Abstract

3D printing is the technology in which three dimensional solid objects can be created from a digital model. The objective of this review is to describe some of the recent developments in the application of 3D printing to medicine. The methodology involves the critical review of the topic through different authentic scientific sources such as Science Direct, Google, Google Scholar and etc. with the help of appropriate key words. 3D system provide opportunities to medical and pharmaceutical industries to design more specific and authentic drug delivery system, high productivity of surgical and implants, more précised and personalized health care system and it is also helpful to save the life of people due to any organ failure or damage in case of any accidents or diseases. 3D printing is used to generate models, research, medical education, surgical tools, drug delivery system and implants. 3D printing has great potential for future use in the biomedical field and will bring a revolution in the health care system

Keywords: 3D Printing, Drug, Health care, Medical application

Introduction

3D printing is the technology in which three dimensional solid objects can be created from a digital model. 3D printing has opened the doors and areas of people associated with the medical and health care system. Now, the medical, health care and pharmaceutical companies can able to produce more rapid manufacturing of products. The quality of the product should be more specified and can be easily monitored. This technology is expanding rapidly and is expected to bring revolution in the field of medical, pharmaceutical, and health care system (Arun, 2018).

Medical applications for 3D printing are expanding rapidly and are expected to revolutionize health care (Schubert et al., 2014). The American Society for Testing and Materials (ASTM) International Committee F42 has adopted the term additive manufacturing (AM) for techniques that produce physical objects from three-dimensional (3D) digital data via the “process of joining materials to make objects from 3D model data, usually layer upon layer, as opposed to subtractive manufacturing methodologies” (A.I. Committee et al., 2009).

3D printing, also known as additive manufacturing, is based on the principle of layered manufacturing, in which materials are overlapped layer by layer. This technology can be used to quickly fabricate components with any complex shape by accurately accumulating material using solid modeling according to a computer aided design (CAD) model or computed tomography (CT) scan under computer control (Yeong et al., 2006). The 3D printing industry has recently exploded due to the reduced manufacturing costs of 3D printers and to their improved printing precision and speed, allowing for huge advances in medical equipment, implant material, and cell printing. The preparation of organ models, rapid manufacturing of personalized scaffolds and direct printing at the defect site can be achieved by 3D printing technology based on a patient’s imaging data such as CT or magnetic resonance imaging. In this way, 3D printing technology brings new possibilities for building bionic tissue or organs and solving the donor-shortage problem (Butscher et al., 2013).

This refers to a series of industrial AM processes commonly referred to as 3D printing, which employ computer-automated manufacturing (CAM) processes to fabricate physical 3D objects layer by layer from computer-aided design (CAD) models. Thus additive manufacturing, commonly known as 3D printing, is a manufacturing method in which objects can be created by fusing or depositing materials onto, or into, a substrate. The materials deposited can be powders, plastics, ceramics, metals, liquids or living cells, making the process hugely versatile. The process is also repeatable, accurate, and cost-effective for small production runs, allowing the reliable production of customized parts. It also allows fast production and collaboration between physicians and researchers, who can now share a physical object over the internet and recreate it quickly with high precision (Sidambe, 2014).

3D printing finds application in the field of biomedical from 2000 onwards. For the first time, technology is used in the fabrication of dental implants. Recently, 3D printing is used in the fabrication of bones, skeletons, ears, jaws, blood vessels, tissues, and organs. The novel use of 3D printing involves tissue fabrication, implants, model fabrication, drug discovery, research, and designing of dosage forms (Klein et al, 2013). 3D printing is highly growing and important technology plays a great role in medicine and different disciplines. This review focuses on the medical applications of 3D printing and its implications for medical application

2. A Review On 3d Technology On Medical Applications And Its Impacts

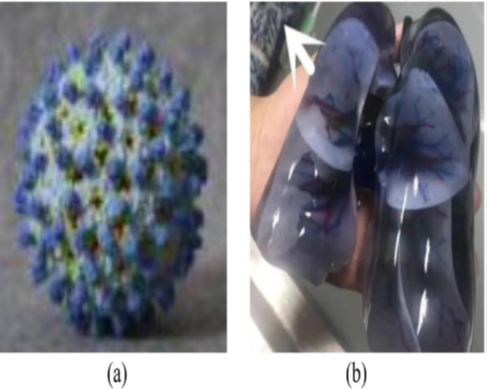

2.1. 3D printing medical model

One of the most popular uses of 3D printing is in dentistry. As there are many reports on this aspect, this paper will not review it. In addition, another wide application of 3D printing is in medical education and operation planning. Based on the image data collected by CT, MRI and other scanning equipment, the 3D printing medical model can be used for operation pre-planning, medical education and doctor-patient communication. Figure 1 shows model of new coronavirus and the infected lung, which is used to popularize the knowledge of new coronavirus. More and more medicine subjects, such as orthopedics, neurosurgery and oncology, use 3D printing medical model to pre-plan operation and improve success rate of the operation and reduce the risk. The more difficult the operation meets, the more valuable to plan the operation through 3D printing model is (Wang and Li, 2016). A typical application is in the accurate resection of mediastinal tumor. In order to avoid damaging the surrounding important tissues such as trachea, cardiovascular and nerve when cutting the deep tumor, the double source spiral CT was used to obtain data and make the 3D printing model of the tumor and its adjacent organs. The best operation path and approaching skills were explored in the pre-operation to improve the success rate of operation (Sun et al., 2018).

At present, 3D printing technology in medical model needs to be improved in the following two aspects: one is 3D medical modeling technology; the other is the integration among medical modeling, 3D printing process and medical diagnosis process (Hu et al., 2019).

Figure 1. medical model via 3D printing technology. (a) cornavirus;(b) infected lung (Wang et a.,l 2016).

2.2. Printing tissues and organs

Tissue or organ failure is a major biomedical problem. The reasons for this problem include increased age, diseased states, road accidents, etc. Transplantation is not only expensive but there is also a deficiency of the organs to transplant. Further, it is very difficult to find the person who is ready to donate organs and secondly there would the chances of tissue rejection. To avoid these problems associated with tissue and organ implants the technology of tissue engineering has been explored. Rather than using conventional tissue engineering, the 3D printing offers various advantages like appropriate cell placement, cell concentration and size control, control on speed. 3D printing can be used in organ printing (Ozbolat and Yu, 2013). There are different 3D printing systems are used which includes laser-based, inkjet, extrusion-based but a part of all inkjet printing is used to produce organs and human tissues. Nowadays the researchers are using bio-printer to fabricate valves of the heart, joints, bones, spiral disk, and ear. Wang et al. produced artificial liver by depositing the different cells in hydrogels. For the fabrication of artificial liver, 3D bioprinting is used (Alhnam et al., 2016).

2.3. Drug delivery

Personalized 3D-printed drugs may particularly benefit patients who are known to have a pharmacogenetic polymorphism or who use medications with narrow therapeutic indices.

Pharmacists could analyze a patient’s pharmacogenetic profile, as well as other characteristics such as age, race, or gender, to determine an optimal medication dose. A pharmacist could then print and dispense the personalized medication via an automated 3D printing system. If necessary, the dose could be adjusted further based on clinical response (Ursan et al., 2013). 3D printing also has the potential to produce personalized medicines in entirely new formulations such as pills that include multiple active ingredients, either as a single blend or as complex multilayer or multi reservoir printed tablets. Patients who have multiple chronic diseases could have their medications printed in one multi dose form that is fabricated at the point of care. Providing patients with an accurate, personalized dose of multiple medications in a single tablet could potentially improve patient compliance (Khaled et al, 2014). Ideally, compounding pharmacies could dispense 3D-printed drugs, since their customers are already familiar with purchasing customized medications (Ursan et al., 2013).

Researchers at University College London have fabricated topical drug delivery systems using 3D bioprinting. They investigated fused deposition modeling (FDM) and stereolithography (SLA) for the fabrication of devices to be worn on the nose and deliver salicylic acid for the treatment of acne. The salicylic acid is loaded into commercial polymer filaments using hot melt extrusion. 3D printing lends itself to this process, as scanned images of the patient’s anatomy can be used to create devices that fit exactly, maximizing contact and delivering an even dose of the drug. They found that while both methods created suitable devices, the SLA method was more convenient as a fabrication process. The dosage can also be varied when the filaments used for printing are prepared (Goyanes et al., 2016).

2.4. Surgical tools and surgical planning

Computer-Aided Design is an effective tool in the present scenario for meeting the needs and demands of the operation theatre. The 3D printed tools can be effectively used for cuts and sutures. The 3D printed tools have advantages in terms of emergencies and it is more beneficial in developing countries because of its cost-effectiveness (Rankin et al., 2014). The individual variances and complexities of the human body make the use of 3D-printed models ideal for surgical preparation (Klein et al., 2013). Having a tangible model of a patient’s anatomy available for a physician to study or use to simulate surgery is preferable to relying solely on MRI or CT scans, which aren’t as instructive since they are viewed in 2D on a flat screen (Gross et al., 2014). The use of 3D-printed models for surgical training is also preferable to training on cadavers, which present problems with respect to availability and cost.3 Cadavers also often lack the appropriate pathology, so they provide more of a lesson in anatomy than a representation of a surgical patient (Banks, 2013).

Operational surgery on a complex congenital heart requires a highly skilled and experienced surgeon who can also make quick decisions during the operation. Making instantaneous decisions during the operation inevitably may lead to longer operating times, which may cause adverse impacts on the surgical outcome. Vodiskat et al. used 3D printing model of the congenital heart defect used for preoperative planning. They have employed two different commercially available 3D printing technologies (Polyjet Objet Eden 350, MakerBot Replicator) for reconstruction of the congenital heart defect in three different patients Vodiskar et al., 2017).

Figure 2. Researchers at the National Library of Medicine generate digital files from clinical data, such as CT scans, that are used to make custom 3D-printed surgical and medical models (National Institutes of Health, 2014).

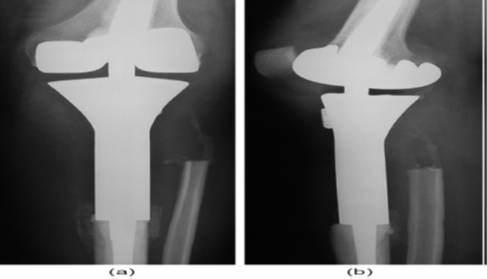

2.5. Implants

Permanent medical implants commonly used in dentistry and orthopedics require non-degradable biomaterial and offer good biocompatibility after surgical operation. Compared with fabricating implants by means of traditional machining technology, 3D printing can achieve personalized real-time manufacturing of a complex implant with high dimensional accuracy and short production cycles. During traditional bone treatments, stress shielding phenomena can easily occur because traditional metallic implants present greater stiffness than bone, which will eventually compromise bone integrity. Integrating topology-optimization designs with 3D printing is a new and effective technology to fabricate lightweight customized implants with adjusted stiffness] (Altamimi et al., 2017).

Wong et al. designed and printed the implant according to the shape and biomechanical analysis of pelvic defect after tumor resection (Wong et al., 2015). The operation result showed that the patients could walk independently and the hip joint recovered well. In order to promote the fusion and reduce the stiffness mismatch between bone cells and implants, Shah et al. simulated the ultra-structure of natural bone canaliculus, designed a porous channel (Shah et al., 2016). The morphology of bone cells showed that the 3D printed implants grew well with the human interface tissue, which was helpful to eliminate the stress shielding effect and promote the bone healing better. In addition, 3D printing elastic film implants can be used to treat heart disease, and 3D printing nerve guide tubes can be used to guide the nervous system to finish self-repairing (Gao et al., 2017). Zhang et al. designed and manufactured custom joint prostheses according to the osseous morphology of resected proximal tibial osteosarcomas (Zhang et al., 2008). Figure 3 show postoperative imaging of a custom prosthetic reconstruction (Galasso et al., 2010).

Figure 3. postopreative (a) anteroposterior and (b) lateral radiographs of custom prosthetic reconstruction (Galasso et al., 2010).

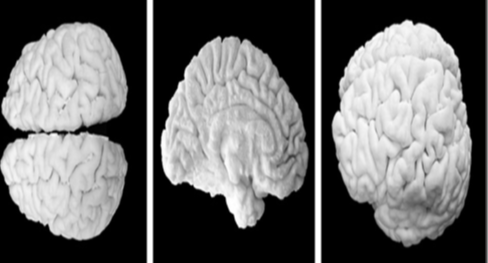

2.6. Medical Education and Training

In general, 3D-printed models are anatomically accurate, provided that high quality CT scan data are available. However, in many cases 3D-printed models are typically inflexible, which makes application difficult in cases involving soft tissue, such as the brain. Ploch et al. proposed a very fast and cost effective method using combined 3D printing, molding, and casting, to create realistic models of human brains which are physiologically accurate as well as deformable. They used a surrogate gelatin-type material that closely mimics the mechanical properties of the human brain. Their models are shown in Figure 3. They concluded that this technique can be used to make personalized deformable brain models, which can be used for surgical planning or for medical training (Ploch et al., 2016).

Figure 4. Anatomically accurate 3-D printed brain model (Wang et al., 2016).

Several imaging processes are used in radiology to capture 2D images of the human body but the most common technologies remain CT and MRI. For both methods, contrast agents are injected into the patients before each acquisition for a better distinction between the tissues by enhancing the contrasts of the structures of interest. Controlling the noise and resolution of the images also impacts on the quality of the 2D images. A very high resolution of data imaging is always recommended; however, depending on the needs and the capabilities of the 3D printer selected for the fabrication, high resolution may not be required. As will be reviewed later, only a few printing technologies and apparatus models can reproduce very fine details (Ogden et al., 2015).

2.7. Medical research

The development of 3D printing for modeling the behavior of cancers has a huge impact on assessing the viability of the responses of the various forms of the disease to different treatments. Using HeLa cells, researchers at TsingHua and Drexel Universities have defi ned a process to deposit HeLa cells into a 10 x 10 x 2 mm hydrogel structure to create synthetic cervical tumors to investigate the growth of the disease (Zhao et al., 2014). Alongside this, they created similar tumors using existing 2D methods. They report that their model showed different behavior from previous 2D models, proliferating more quickly and forming cellular spheroids. They note that this method can be especially effective if combined with techniques to deposit multiple types of cell, and investigate the microcellular tumor environment. The development of microfluidics in bio printing allows better control over experiments on 3D cell cultures, and the move towards more complex tissue structures like those in native tissues. Researchers at Drexel University have created cell-laden 3D microfluidic structures embedded in PDMS with improved leak protection compared with existing structures (Snyder et al., 2016). This innovation allows them to guide cells through the microfluidic network to create complex tissue structure. They report a material deposition repeatability of 10 μm with their custom-made deposition apparatus, and the capacity for heterogeneous cell co-cultures using a dual nozzle process. This is part of a large body of work improving the integration of microfluidics with cell cultivation to facilitate all kinds of medical research. 3D printed cells in hydrogel scaffolds have been used by researchers in the University of Dresden to grow cultures of microalgae and microalgae/human cell combinations. The microalgae, exposed to light, were able to grow quickly and the chlorophyll content increased 16-fold over the first few days. The microalgae were capable of delivering oxygen to the human cells closely patterned in their midst. The researchers claimed that the principle of such a technology delivering oxygen or secondary metabolites as therapeutic agents was proven, but noted that much effort was still required to bring about any feasible therapies with their technology (Lode et al., 2015).

Conclusion

Great progress has been made in the field of medical-oriented 3D printing technology. The manufacturing technology of organ models and permanent implants has become more mature. 3D printing is a method for conveniently creating customized one-off objects, and is transformative in a great number of medical applications. With the development of printing techniques and materials suitable for particular medical applications, research interest is increasing. The recent developments described here show that, while exciting and important advances have already been made in areas of research, teaching, surgical planning, applications like personalized drugs and organ printing are at an early stage of development. Therefore, 3D printing technology should practice for the development of medicine through;

- The use of 3D printing technology for medical applications will efficiently solve the donor-shortage issue for organ transplantations.

- It is an emerging and rapidly developing interdisciplinary field that tightly integrates material science, biology, and clinical science.

- For researcher’s help to solve the problems by successfully integrate 3D printing with tissue engineering.

References

-

3D Print Exchange. National Institutes of Health. Available at: http://3dprint.nih.gov. Accessed July 9, 2014

Publisher | Google Scholor -

A.I. Committee, ASTM International Committee F42 - Additive Manufacturing Technologies, ASTM F2792-12 Standard Terminology for Additive Manufacturing Technologies, American Society for Testing and Materials,West Conshohocken, PA, 2009.

--> -

Alhnam MA, Okwuosa TC, Sadia M, Wan K-W, Ahmed W.Emergence of 3D Printed Dosage Forms: Opportunities and Challenges. Pharm Res. 2016;33(8): 1817-1832.

Publisher | Google Scholor -

Altamimi AA, Fernandes PRA, Peach C, Cooper G, Diver C. Metallic bone fixation implants: a novel design approach for reducing the stress shielding phenomenon. Vitr Phys Prototyping 2017;12(2):141–51.

Publisher | Google Scholor -

Banks J. Adding value in additive manufacturing: Researchers in the United Kingdom and Europe look to 3D printing for customization. IEEE Pulse 2013;4(6):22–26.

Publisher | Google Scholor -

Butscher A, Bohner M, Doebelin N, Hofmann S, Müller R. New depowderingfriendly designs for three-dimensional printing of calcium phosphate bone substitutes. Acta Biomater 2013;9(11):9149–58.

Publisher | Google Scholor -

Galasso O, Mariconda M, Brando A, Iannò B. Disassembly of a distal femur modular prosthesis after tumor resection. J Arthroplasty 2010;25(2):334.e5–9.

Publisher | Google Scholor -

Gao, X.B., Wang, L.H. and Liu, H.H. (2017) Main Application of 3D Printing Technology in Medical Industry. Smart Health, 3, 5-8.

--> -

Goyanes, A., Det-Amornrat, U., Wang, J., Basit, A.W. and Gaisford, S., 2016. 3D scanning and 3D printing as innovative technologies for fabricating personalized topical drug delivery systems. Journal of Controlled Release, 234, pp.41-48.

Publisher | Google Scholor -

Gross, BC, Erkal JL, Lockwood SY, et al. Evaluation of 3D printing and its potential impact on biotechnology and the chemical sciences. Anal Chem 2014;86(7):3240–3253.

Publisher | Google Scholor -

H. Arun, Healthcare 3D Printing Market 2018 ProminentPlayers-Aprecia Pharmaceuticals, Aspect Biosystems, Bio 3D Technologies, Biobots, Cyfuse Biomedical, Digilab, 3 Dynamics Systems, Envision Tec, Luxexcel, Materialise NV, Nano 3D Biosciences, Oceanz, Organovo Ho.http://www.openpr.com. accessed date 25.05.2020

--> -

Hu, J.Y., Li, Y.W., Zhang, Y.Q., et al . (2019) Application Progress of 3D Printing Technology in Clinical Medicine. Shandong Medical Journal , 59, 106-109.

Publisher | Google Scholor -

Khaled SA, Burley JC, Alexander MR, Roberts CJ. Desktop 3D printing of controlled release pharmaceutical bilayer tablets. Int J Pharm 2014;461 (1–2):105–111.

Publisher | Google Scholor -

14. Klein GT, Lu Y, Wang MY. 3D printing and neurosurgery— ready for prime time? World Neurosurg 2013;80(3–4):233–235

Publisher | Google Scholor -

Lode, A., Krujatz, F., Bruggemeier, S., Quade, M., Schutz, K., Knaack, S., Weber, J., Bley, T. and Gelinsky, M., 2015. Green bioprinting: Fabrication of photosynthetic algaeladen hydrogel scaffolds for biotechnological and medical applications. Engineering in Life Sciences, 15(2), pp.177-183.

Publisher | Google Scholor -

Ogden KM, Aslan C, Ordway N, et al. Factors affecting dimensional accuracy of 3-D printed anatomical structures derived from CT data. J Digit Imaging 2015;28:654–63.

Publisher | Google Scholor -

Ozbolat IT, Yu Y. Bioprinting Toward Organ Fabrication: Challenges And Future Trends. IEEE Trans Biomed Eng 2013;60(3):691–699.

Publisher | Google Scholor -

Ploch, C.C., Mansi, C.S., Jayamohan, J. and Kuhl, E., 2016. Using 3D printing to create personalized brain models for neurosurgical training and preoperative planning. World neurosurgery, 90, pp.668-674.

Publisher | Google Scholor -

Rankin TM, Giovinco NA, Cucher DJ, Watts G, Hurwitz B, Armstrong DG. Three-Dimensional Printing Surgical Instru¬ments: Are we there yet? J. Surg. Res. 2014, 189(2):193–197.

Publisher | Google Scholor -

Schubert C, van Langeveld MC, Donoso LA. Innovations in 3D printing: a 3D overview from optics to organs. Br J Ophthalmol 2014;98(2):159–161.

Publisher | Google Scholor -

Shah, F.A., Snis, A., Matic, A., et al . (2016) 3D Printed Ti6Al4V Implant Surface Promotes Bone Maturation and Retains a Higher Density of Less Aged Osteocytes at the Bone-Implant Interface. Acta Biomaterialia , 30, 357-367. https://doi.org/10.1016/j.actbio.2015.11.013

Publisher | Google Scholor -

Sidambe, A.T., 2014. Biocompatibility of advanced manufactured titanium implants — A review. Materials, 7(12), pp.8168-8188.

Publisher | Google Scholor -

Snyder, J., Son, A.R., Hamid, Q. and Sun, W., 2016. Fabrication of microfluidic manifold by precision extrusion deposition and replica molding for cell-laden device. Journal of Manufacturing Science and Engineering, 138(4), p.041007.

Publisher | Google Scholor -

Sun, T., Han, S.Q., Wang, J.W., et al . (2018) Value of 3D Printing Technology in Precise Resection of Mediastinal Tumors. Chinese Medical Equipment Journal , 39, 54-56, 78.

Publisher | Google Scholor -

Ursan I, Chiu L, Pierce A. Three-dimensional drug printing: a structured review. J Am Pharm Assoc 2013;53(2):136–144.

Publisher | Google Scholor -

Vodiskar, J., Kütting, M., Steinseifer, U., Vazquez-Jimenez, J.F. and Sonntag, S.J., 2017. Using 3D physical modeling to plan surgical corrections of complex congenital heart defects. The Thoracic and cardiovascular surgeon, 65(01), pp.031-035.

Publisher | Google Scholor -

Wang, D.Q. and Li, B. (2016) Development of Application Study on 3D Printing Technology in Medical Field. Chongqing Medicine , 45, 126-128.

--> -

Wang, K., Zhao, Y., Chang, Y.H., Qian, Z., Zhang, C., Wang, B., Vannan, M.A. and Wang, M.J., 2016. Controlling the mechanical behavior of dual-material 3D printed meta-materials for patient-specific tissue-mimicking phantoms. Materials & Design, 90, pp.704-712.

Publisher | Google Scholor -

Wong, K.C., Kumta, S.M., Geel, N.V., et al . (2015) One-Step Reconstruction with a 3D-Printed, Biomechanically Evaluated Custom Implant after Complex Pelvic Tumor Resection. Computer Aided Surgery , 20, 14-23. https://doi.org/10.3109/10929088.2015.1076039

Publisher | Google Scholor -

Yeong WY, Chua CK, Leong KF, Chandrasekaran M, Lee MW. Indirect fabrication of collagen scaffold based on inkjet printing technique. Rapid Prototyping J 2006;12(4):229–37.

Publisher | Google Scholor -

Zhang Y, Yang Z, Li X, Chen Y, Zhang S, Du M, et al. Custom prosthetic reconstruction for proximal tibial osteosarcoma with proximal tibiofibular joint involved. Surg Oncol 2008;17(2):87–95.

Publisher | Google Scholor -

Zhao, Y., Yao, R., Ouyang, L., Ding, H., Zhang, T., Zhang, K., Cheng, S. and Sun, W., 2014. Three-dimensional printing of Hela cells for cervical tumor model in vitro. Biofabrication, 6(3), p.035001.

Publisher | Google Scholor